Interview with Grand Voyage Records

(Photo copyright: Cyril Perregaux)

I’ve been collecting records ever since I inherited a collection of them when I was 18-19 years old. The collection has grown over time, even more so since I moved to Switzerland and came across Heavy Weight Music (which is unfortunately closing in January 2026), as well as beginning Reverb Dream. It’s always great to have a physical version of the EP/albums that we love and it’s a bonus when there is something special about the design of the record itself or the artwork.

I had seen a record from Grand Voyage Records without even knowing about the background of the record but I was really impressed by the design of the limited edition single from Emzyg, ELY / AKARI, which had fluorescent sand within in the record.

Recently, Kevin Galland released his solo album, In the Silence Between Worlds on limited handmade vinyl and shortly before my holiday, I met Mathieu from The Last Wolf and received a copy of his fantastic album, Another Kind Of Blue. Not only was it a limited edition with a fitting marble blue colour, I was recommended by him to interview Grand Voyage Records who created the album and I am very thankful for this suggestion.

Whilst researching the article, I was also reminded of the vinyl record production problems in 2021 and 2022 due to a number of reasons including a limited number of pressing plants, pandemic-related issues and raw material shortages. However, in the canton of Valais, Switzerland already had its unique answer to the crisis and especially for independent bands and labels. Instead of going with 100-200 copies (or even more) whilst being uncertain if they would all be sold, Grand Voyage fulfils orders of one single copy to a hundred with a variety of excellent and innovative designs.

I would like to thank Loris from Grand Voyage Records for taking the time to reply to my questions and with providing more details about his fascinating and unique work.

Introduction:

Tell us about yourself and your experience in music

My name is Loris Ruchet. I am the founder of Grand Voyage Records.

I play double bass in different projects (Coconut Kings, La Maraude, La Banda Mojo Reunion). I started playing guitar as a teenager. At this time, I was more into punk rock culture. I’ve always been attracted by the DIY approach of that scene. It is still my way of doing stuff today. When I was 20 years old, I bought a double bass and after some months of playing Willie Dixon classics all day long in my living room, The Coconut Kings were born. It is still my main music project today. And my main friends by the way!

What is your record collection like? Do you have many coloured records/records with unique designs?

Surprisingly, my collection is not so impressive. I have maybe 400 records that I’ve bought over the last 20 years. So, a bit more than one per month. In parallel to this collection, I also have all the projects I’ve cut since the beginning of Grand Voyage, which is about 150 projects. These records are probably the most unique ones in my collection. I also have an R&D (research and development) shelf with some bizarre objects including multi-groove, shaped records, liquid filled, etc. There is no limit!

I also have records that I bought specifically because of the challenging cutting process. The craziest example is Jack White’s Lazaretto cut by George Ingram at Third Man Records. There are so many tricks on this record that I do not have time to list it here. But dude, this is hard work believe me!

Right with the Coconut Kings circa 2022

How did Grand Voyage Records begin? Where did the idea come from? Do you have any inspirations?

As I remember my mind has always been blown by the cleverness of the playback process of a turntable. You know the fact that more than hundred years ago some people said “hey, let’s try to catch and trap vibrations on to a physical material to take a picture of the sound”. The basic process was so simple and after decades of improvement we reached the high-fidelity sound of the vinyl record that we all know nowadays. So, it started with this fascination.

Soon after, I spent a whole rainy night building a DIY cutting tool that basically consisted of one sewing needle stuck in a broken computer speaker coil. Using a disco ball motor with some glue and tape, a turntable and an old CD, I was now able to put sound into a physical object that could be played back on a regular turntable. That was a “Lo-lo-fi” result, but the sound was there and audible and it was all made from scrap in a few hours. From that day, I continued to improve the process. In parallel I bought a brand-new cutting lathe. Not the best sound but affordable and a nice way to start. It was my first stereo lathe. With that tool I was now able to cut hi-fi stereo records.

I started by doing small runs of dubplates for my own bands. Then I had requests from my friend’s band. Suddenly, unknown people started to ask as well. So, I decided to build a more professional cutting lathe. Based on some research (especially from George Neumann design and schematics), a lot of help from the “lathe troll community” and dozens of prototypes, the goal was to increase quality and process. I have now four lathes running in parallel in the studio. Equipped with the finest element (FlokaSon cutting head, Matsushita direct drive motor, homemade vacuum platter, homemade pitch control, homemade depth-controlled suspension box…)

What sort of training/education did you do to produce records?

As you can imagine there is no official school/apprenticeship for the job! I started a precision mechanic apprenticeship when I was 14. Then I studied mechanical engineering. These studies helped me a lot to understand the process and to build my own tools. Together with my musician background, my interest in art and the hours spent behind a DAW trying to record my projects, I figured out that I had all the cards in my hand to start cutting my own records. I am proud and happy to use what I’ve learned at school into something that makes me feel useful and part of the musical, artistic and cultural field instead of working for Nestle 5 days a week doing nonsensical, bad things to the planet.

In parallel to the cutting process, I also had to understand the basics of printing and graphic designing. I quickly figured out that nobody was interested in a vinyl record without the jacket and without the center labels. Of course, I am not becoming a graphic designer nor a printer, but I learned the language and I can understand the limitations better and explain them to my customers.

The apprenticeship in that specific vinyl record field is an everyday learning exercise. I keep being surprised and face issues every week. That can be very annoying, but it makes me learn a bit more every day and I always feel happy when I have learned something at the end of the day.

Did you have the studio and equipment before you had customers? How did that work?

As I said before, I started cutting records without any plan. At the beginning I was just fascinated by the process, and I wanted to understand it. At that time, I’d never have thought I would make a business out of it.

(Photo copyright: Cyril Perregaux)

How would you describe Grand Voyage Records in your own words?

Such a difficult question! As a short answer I would describe as follow: Grand Voyage is a one-man artisanal structure that can put your music on vinyl without minimum quantity per order and with a huge variety of special products.

To me, Grand Voyage is located at the crossroads of physics and art. The main activity is of course to give an alternative to the pressing process, which is not always suitable for small quantities and fast production. Many pressing plants do not offer the ability to make less than 100 records. In today’s digital world, most bands do not need thousands of vinyl records to be listened to. Cutting small amounts of records is also helping storage and avoiding waste.

Besides cutting records, I am also involved in artistic projects using my technical knowledge for helping installations in artistic exhibitions. I am also doing art using my experience with analog recording process.

Do you work mainly with Swiss artists/labels? Do you have recurring customers?

Yes, I work mainly with Swiss artists and labels. The shorter the circuit, the better! Most of the time I am directly in contact with the artist or their manager. Sometimes I work with record labels such as Humus, Cheptel, Two Gentlemen amongst others. I am also proud to help smaller record labels such as Le Chat Records, Road Sweet Road, Sunday Fog, Table Basse Records, Blizzard Audio Club, Mini Distro Label, Augeil Records, Cold Smoke Records,…

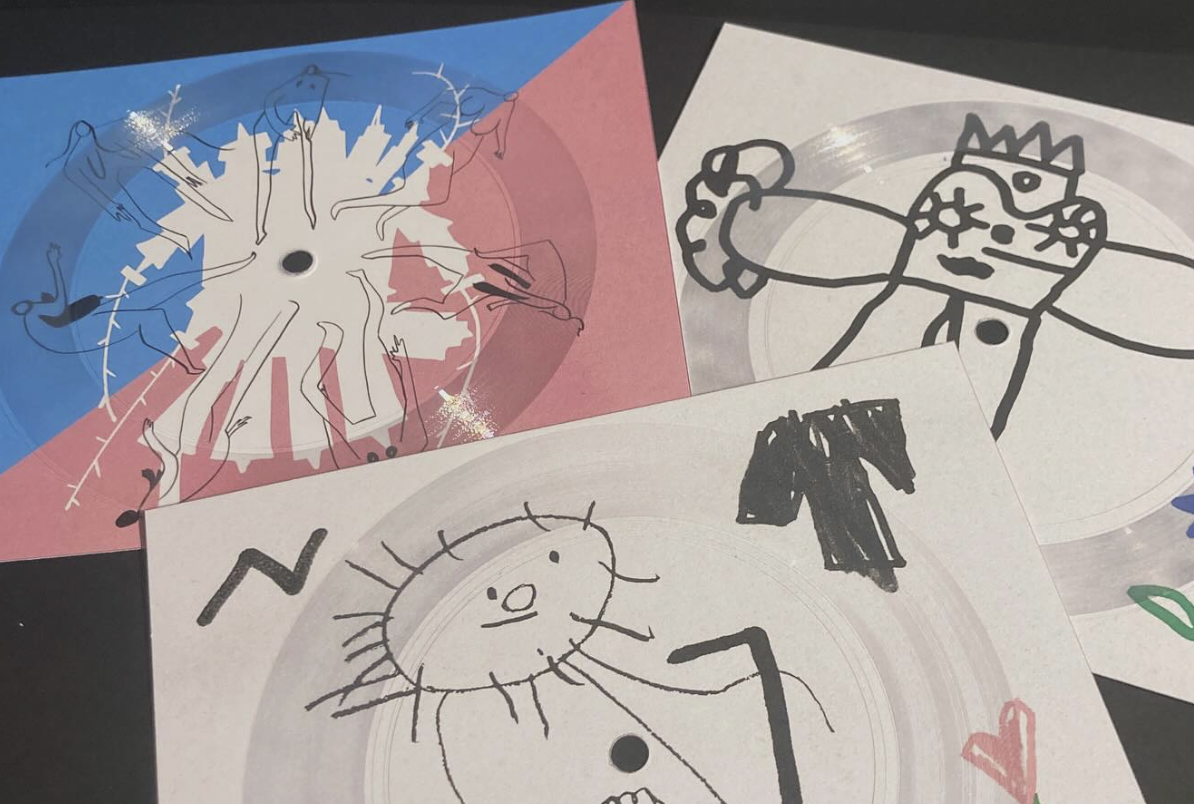

(Photo copyright: Cyril Perregaux)

The process

Tell us about the process from start to finish - when a musician/a label places an order to the final product

I always try to understand the needs of the customer. Some know exactly what they want, while others don’t know and are asking for ideas. At this stage we discuss all the options, prices and lead-time. If needed, we can fix a rendezvous to discuss everything and have a coffee. Most of the time everything is done by e-mail or phone.

Usually, a test cut is made before launching the production. This includes the elements of the final product (record, jacket, center label, insert, etc.). This stage can be done in 1-2 weeks as I am directly in contact with the printers. It is then possible to check the test and to adjust both the printing and the cutting to have the most satisfying product possible.

When the customer gives me the green light, I start production. It can take from 4 to 10 weeks depending on the project and my workload. Sometimes I must rush and can do it in 2 weeks, but it is never the best way to work.

The product

Which products/types of records do you offer?

I must say that the black vinyl record remains the best seller as it is the cheapest option for the best quality. Colored records are of the same quality but are more expensive since the manufacturing process of the blank disc is more complex. Almost all colors are available. It is even possible to have a different color on side A than on side B. For The Hello Future Me album from Elie Zoé, we even made together a special hand painted edition. Elie came to Valais with some artwork, and we spent one day together manufacturing the 50 unique blank records. That was a nice experience.

Laserdiscs are also popular, although they do not give the best sound quality.

In term of size, every option are available in 5’’, 7’’, 10’’ and 12’’.

In term of “cutting tricks” it is possible to do loop, endloop, cutting inside-out, multigroove (roulette records), etc.

Very special records, filled with stuff such as sand, tobacco or even flowers, are also available in small quantities. Sure, this is another budget but, dude, it has almost no limit and can be cool for special editions or birthday presents.

Do you have a favourite product?

I kind of like the LaserDisc idea. You know so many LaserDiscs were made before the invention of the DVD. Today it is difficult to find a LaserDisc Player. So, using and cutting grooves on them to record sound gives them a second life. This is a nice way to upcycle.

I really like Audio Postcards. It’s a perfect mix of nice artwork matching a nice song and can easily be sent all over the world. It makes art travel.

I also really like the history behind “bone records” that was a common underground DIY way of spreading music in the USSR when western artists were forbidden.

Have you noticed a favourite product amongst the bands/labels?

As I said, the black standard is the best seller. For singles, a lot of people ask for the audio postcards. It’s a nice thing to have at the merch’ stand after a gig.

How do you invent new ideas/new products?

I must say that when I started cutting records, every material that I was seeing was a potential “cutting material”. I’ve tried so many things from picnic plates to Alp’s cheese. I do not have a recipe of how I invent it, the ideas come from everyday life. Sometimes it works, sometimes it is only fun to try.

Which is the hardest product to make?

They all have their own difficulties. Whatever the physical support, cutting a nice groove that sounds good is always challenging. Of course, it becomes harder when you have a lot of information on one side. Then, if you add a special option such as sand filled on such a tricky groove it doubles the pain, it triples the sweat.

How is the splatter technique done?

The splatter effect that everybody knows today is directly linked to the pressing technic. I cannot have the same result, but I can do something similar and a lot of other patterns that are not possible with the pressing process. The records are hand painted and prepared before being cut. It’s time consuming but apart from it, there are no limits.

How do you test the records with regards to needles?

There are two steps to test the record quality. The first one is to check what the losses are, technically speaking (stereo image, frequencies, dynamic), generated by the cutting process and its physical limitations. This check is done by playing back the record on a hi-fi system using a high-end cartridge. Once the result is good, I cut the test cut and if the customer approves it, I start the production with these settings.

The second step consists of being sure that all records do not jump when playback and that the signal to noise ratio is correct. For that I play back every record using a common system such as Technics SL1200 with a random spherical cartridge. I also add some more weight on the stylus and set the antiskating to 0. If it sounds good and does not jump, I am pretty sure that every cheap set-up can handle it.

What is a live cutting? How is it done?

Live cutting is a recording method that consists of directly recording the music on the disc. Basically, a band is playing in front of microphones that capture the sound and send it to the cutting lathe. That method was the standard before the invention of magnetic tapes that then gave the ability of “saving” the recording session and gave birth to “editing” and “post-production”. Before the tape, the sound was directly taken from the band and recorded as-is on the disc. That’s how all the 78rpm shellac discs were made for example. Alan Lomax used the same technic for his library of congress recordings collection. In my opinion, that technic is interesting in terms of archive and creation. With this, everything is directly cut in the groove, unremovable. It is a picture of the sound during a defined instant, including potential mistakes. But as you know, there are no mistakes just happy accidents!

Back in the days, industry used this technic and cut into a lacquer disc. From this lacquer they created a mould. With that mould they pressed the records. So the live recording was then available on multiple copies. That is still the same process of making a pressed record today (except for the live recording part that is now mainly made from a computer DAW). Grand Voyage is not live cutting on lacquer. I am using common dubplates (PVC plastic disc). That means that the record cut will be the only copy. Sometimes I organize live sessions where the band/artist are playing the same songs twenty times to have twenty 45rpm singles. That is usually a long day full of fun and sweat, but at the end we have twenty unique records.

What's the process for creating the covers?

It starts with a template sent to the artist. The artist sends me back the template with the artwork on it. Then I gave it to the printing plant. They print it and cut it. Then I have to manually fold it. I am working with different printers depending on the technic and the size of the jacket. As I am only doing small quantities, the offset technic is too expensive. Most of the covers are digitally printed. Although it stays possible to use screen-printing if the artwork is suitable for it. We can of course choose every kind of paper.

Looking back and to the future

What are your memories of the beginning of Grand Voyage Records?

That rainy day I’ve discovered that I could record sound using a sewing needle and a broken computer speaker is a pretty good memory. That night gave me access to a never ending new passion. One of my funniest memories was that exhibition in Manhattan, New York where I had the chance to have been asked for a live cutting workshop. I had to build a portable/dismountable lathe, using a modified electrical toothbrush as a cutting head. That was cool.

What have you learnt since starting the company? What challenges have you encountered?

I learned a lot and I keep learning more and more every day. Cutting record is a lot of patience and it is important to keep trying and trying. The main thing I learnt is that this art is more than 100 years old and it still full of secret. You know, you could think “hey it’s easy we do it since so long”. But at the end, nothing is simple in this industry, from the recording process to the playback experience! It keeps upgrading and I still have a lot to learn about what has been done so far.

What have been your highlights so far?

I would say “every time a customer is happy with my work”.

The Elie Zoé hand painted album I mentioned before is a cool souvenir in terms of sharing. It was such a nice day. Working together with the artist is always a great experience.

Another satisfied customer - Loris with Jona Nido (of Humus Records and Coilguns) in 2021

How does it feel when you complete a record? How does it feel to the artist/label pick up the records and be really pleased with them?

It’s the best return I can have for my work. Sometimes I think of all those records I cut in my small studio in the Alps, travelling in many different places around the world and that they will continue to be there after my death, probably. That makes me feel useful.

What do you plan for the future with Grand Voyage Records?

The plan is to keep on cutting! And doing what I like: making records, feeding my curiosity and sharing with people.

Anything else you would like to add?

I only want to add a big thanks to you for taking time and interest into my world.

Links:

Related articles: